OTEC Support for the Digital Transformation of Your Production System

What does digitalisation mean in the mechanical engineering industry?

One language for all. Machines are already able to provide information about many parameters and send it to devices such as laptops, tablets and smartphones. A global, universal interface, the OPC UA, enables this data to be collected, analysed and evaluated within a local network. The transparent, universal nature of this open interface makes it suitable for all users. This will allow a standard for data interchange between applications from different manufacturers to be introduced without problems. The global production language is becoming a reality.

Ready for the future – consistent production quality

Networked production allows you to improve the coordination of processes across a wide variety of machines, components and systems by providing all the relevant data. You can achieve a high level of automation, which results in increased cost-effectiveness. OTEC has developed its own digitalisation packages so that OTEC customers can take advantage of this. Consequently, the specialist knowledge required to operate the machines and the necessary understanding of the optimum processes and the many parameters can now be used on a custom, flexible basis. Machine control, remote maintenance and self-learning and self-testing machines provide maximum process reliability and use of capacity.

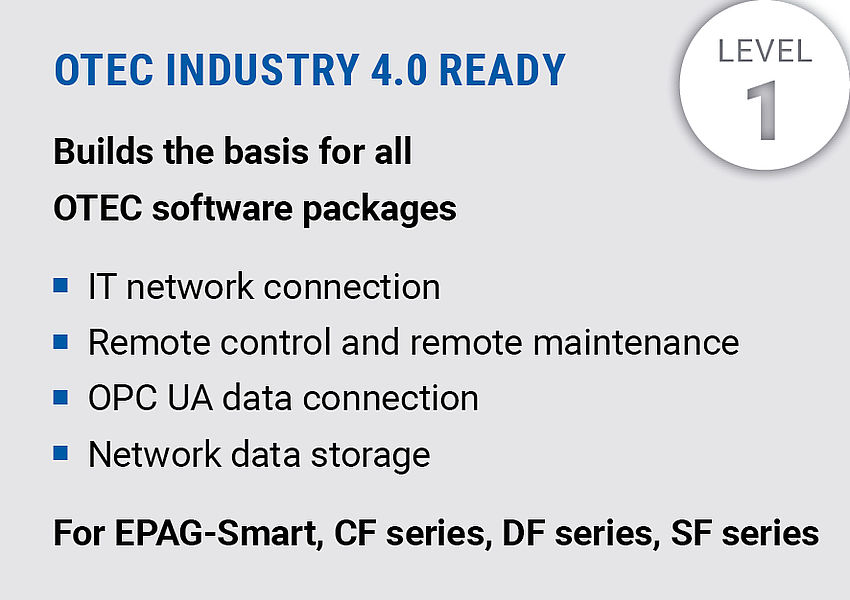

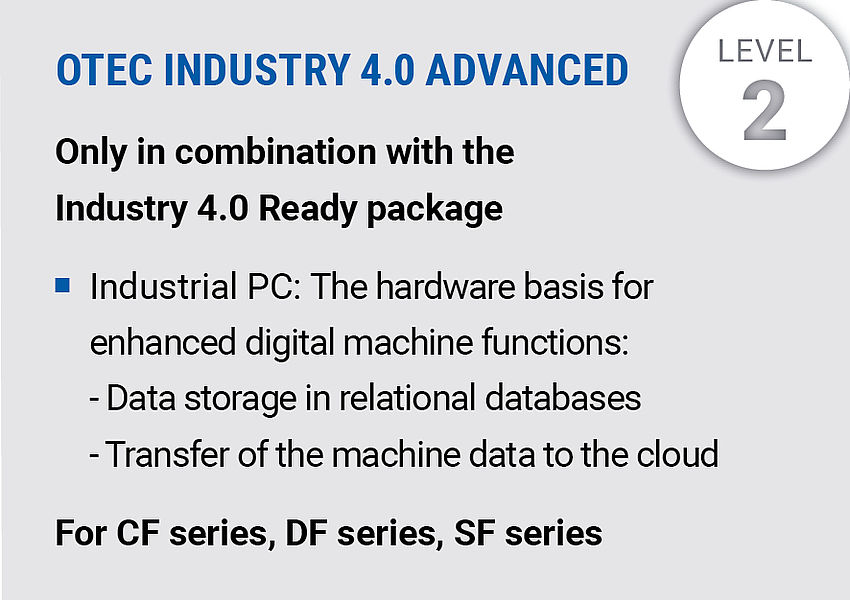

OTEC digitalisation packages: The custom solution for your company

All OTEC machines already come equipped for various levels of digitalisation. Based on your finishing process requirements, you can decide how far you want to take it. Our basic “OTEC Industry 4.0 Ready” configuration is available for all OTEC machines, and our “OTEC Industry 4.0 Advanced” package with an additional industrial PC gives you the option of more advanced digitalisation on CF, DF, and SF machines, enabling cutting-edge machine monitoring and process optimisation via remote maintenance.

![[Translate to Russian:] [Translate to English:] Digitalisierungspakete, Digitalisierte Produktion, Energiemanagementsystem ISO 50001, Nachhaltige Produktion](/fileadmin/uploads/Service/Digitalisierung/otec_digitalisierungspaket_icons.jpg)

Machine performance monitoring and user performance

If you would like the capability to continuously monitor and optimize all running processes, you need to equip your machines with an integrated energy monitoring system (including offline) as standard. This system supports your company during the ISO 50001 certification process, allowing you to continuously improve your energy performance and therefore also minimise your energy costs. OTEC supplies a wide range of tools for these requirements.

OTEC Controlling Tools:

![[Translate to Russian:] [Translate to English:] OTEC Energiemanagement, Energiemonitoring, Controlling Tools, Verbrauchsdatenerfassung](/fileadmin/uploads/Service/Digitalisierung/otec_digitalisierung_energiemonitoring.jpg)

OTEC Energy Monitoring

Records electricity, water and compressed air consumption data. Available in software levels 0 to 2.

For the SF- series

![[Translate to Russian:] [Translate to English:] Energiemanagementsystem, Condition Monitoring, Controlling Tools, Komponentenzustand, Selbstdiagnose, Maschinenstillstand](/fileadmin/uploads/Service/Digitalisierung/otec_digitalisierung_selbstdiagnose.jpg)

OTEC Condition Monitoring

Continuous machine-condition monitoring for self-diagnosis and checks. Options for data collection, analysis, archiving and alerting.

For the SF- series.

![[Translate to Russian:] [Translate to English:] Energiemanagementsystem, ISO 50001, Condition Monitoring, Controlling Tools](/fileadmin/uploads/Service/Digitalisierung/otec_digitalisierung_energiemanagementsystem.jpg)

Energy Management System

Suistainable production thanks to continuous improvement of your company’s energy performance.

OTEC Usability Products (additional user products):

![[Translate to Russian:] [Translate to English:] Barcode-Scanner, Usability Artikel, Benutzer-Zusatzartikel, Programmauswahl, Scancode](/fileadmin/uploads/Service/Digitalisierung/otec_digitalisierung_usabilityartikel_barcodescanner.jpg)

Barcode scanner

simplified machine handling and

process control via QR codes.

![[Translate to Russian:] [Translate to English:] Passwortebene, Datenschutz, Benutzerverwaltung. Passwörter, einloggen](/fileadmin/uploads/Service/Digitalisierung/otec_digitalisierung_usabilityartikel_passwortebene.jpg)

Additional password level

Convenient user management

![[Translate to Russian:] [Translate to English:] Elektronisches Schlüsselsystem, Einloggen, Login, Benutzerberechtigung, Chip](/fileadmin/uploads/Service/Digitalisierung/otec_digitalisierung_usabilityartikel_elektronisches_schluesselsystem.jpg)

Electronic key system

Simple rights management

En route to a sustainable future with OTEC

As a trustworthy global partner, OTEC is setting innovative standards with its machines and their highly reliable

processes. We develop customised pilot applications for our customers and monitor them through all the various

stages to achieve a perfect production process. OTEC digitalisation products equip your business with all the key

tools you need for cutting-edge machine monitoring. And we are happy to help you select the right tools for your

specific process requirements.

Talk to us: HAGEN JOTA Digitalisation Project h.jota@otec.de

![[Translate to Russian:] [Translate to English:] Digitalisierte Produktion, Digitalisierung, IOT, Industrie 4.0, VDMA, OPC UA, Vernetzte Produktion, Predictive Maintenance](/fileadmin/_processed_/c/0/csm_otec_digitalisierung_global_e5dd4cbf34.jpg)