EF-Nova

Automated Surface Finishing for Jewelry Industry.

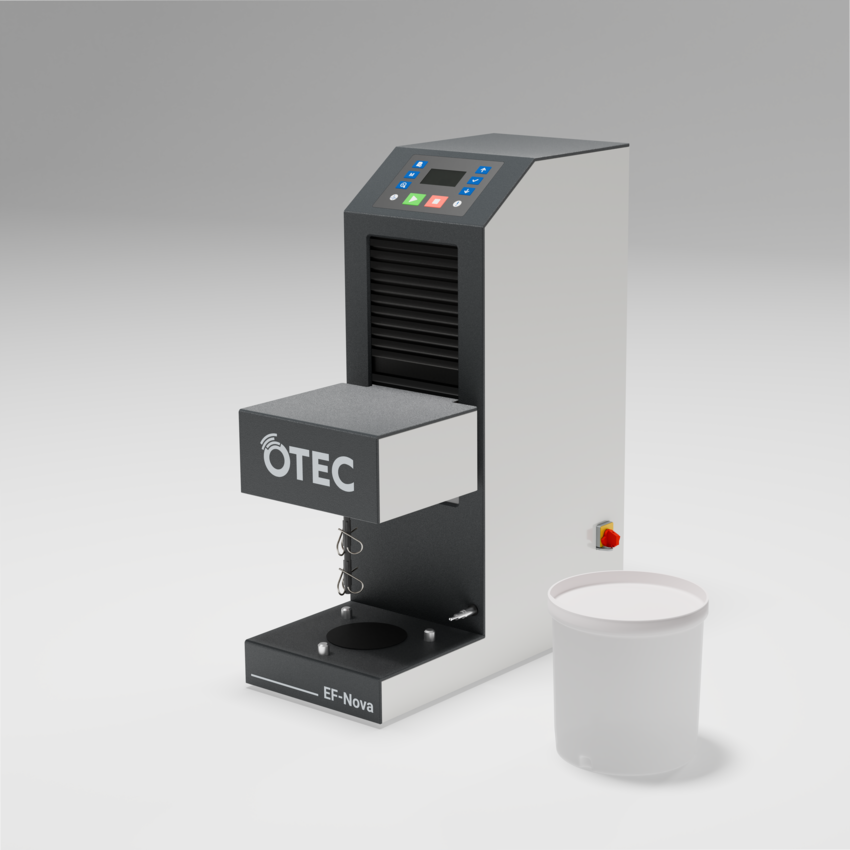

EF-NOVA – SMALL, COMPACT, INNOVATIVE

The jewelry industry is entering a new era in precious metal processing: The EF-Nova complements the already established Eco-Maxi and revolutionizes the finishing process through innovative technology, automated workflows, and a significant reduction in manual postprocessing. It is the perfect combination for intricate geometries and hard-to-reach areas.

Another key highlight is its gold recovery capability, ensuring that no valuable material is lost—an essential advantage for sustainable and efficient operations. At the same time, traditional jewelry finishing methods using polishing or acid baths become obsolete, making the process not only more environmentally friendly but also safer. Instead, user-friendly electrolytes are employed.

Specifically developed for the needs of goldsmiths, small manufacturers, and industrial production, the EF-Nova sets new benchmarks in precision, automation, and user-friendliness.

VERSATILE APPLICATIONS FOR THE HIGHEST STANDARDS

The EF-Nova impresses with its broad material compatibility. It is ideally suited for processing gold, including yellow, red, and white gold, as well as silver, brass, and stainless steel. Thanks to its outstanding performance, it can also process challenging alloys such as White gold-palladium and titanium with exceptional precision—an area where traditional Methods often fall short. Another standout feature is its capacity: Up to six rings can be processed simultaneously, significantly increasing efficiency in workshop operations.

For custom requirements, specialized holders for workpieces such as rings, bracelets, or pendants are available upon request.

EASY OPERATION AND INNOVATIVE TECHNOLOGIES

- Plug-and-Play-System: Quick and straightforward commissioning saves time and reduces training effort.

- Eight pre-installed programs: These can be used without special prior knowledge, making the EF-Nova ideal for beginners and smaller goldsmith workshops.

- Intelligent Media Container Recognition: The container stores information about the process media and operating hours. It enables the corresponding functions accordingly. Through automated assignment, only liquid electrolytes are permitted.

- Guide-through-Menu: A user-friendly navigation system guides the operator through the functions, minimizing errors and increasing production efficiency

AUTOMATION AND PROCESS ADVANTAGES

- Finest finishing: Designed for demanding tasks and hard-to-reach areas, the EF-Nova enables the processing of complex geometries without deforming the workpieces or compromising their integrity.

- Short processing time: With a process duration of only 30 minutes — regardless of the material — the EF-Nova consistently delivers outstanding smoothing and polishing results.

- Significant time and labor savings: The machine reduces labor-intensive manual tasks such as polishing and grinding by up to 90%.

- Efficient maintenance: Quick electrolyte changes ensure minimal downtime and continuous productivity.

- Eco-friendly and sustainable: Up to 100% Gold Recovery: The process enables near-total gold recovery, minimizing material loss.

- Cyanide-free process: The environmentally friendly technology eliminates the use of toxic chemicals such as cyanide, ensuring sustainable and safe processing.

THE SMART CHOICE FOR MODERN JEWELRY FINISHING

With an unbeatable price-performance ratio, the EF-Nova is designed for small and mediumsized goldsmiths who require precise and efficient results—without compromising on quality and flexibility. Thanks to its compact design and innovative features such as the intelligent media container and quick media change technology, the EF-Nova is particularly user-friendly. At the same time, it enables seamless processing of white gold-palladium and titanium — rare

in its price class.

In a market dominated by expensive and complex alternatives, the EF-Nova offers a true solution for cost-sensitive and specialized customers.

Your contact person:

Soran Jota

Managing Director

OTEC Präzisionsfinish GmbH

Heinrich-Hertz-Strasse 24

75334 Straubenhardt

Sales: +49 (0) 7082 / 49 11 711

E-mail: info@otec.de