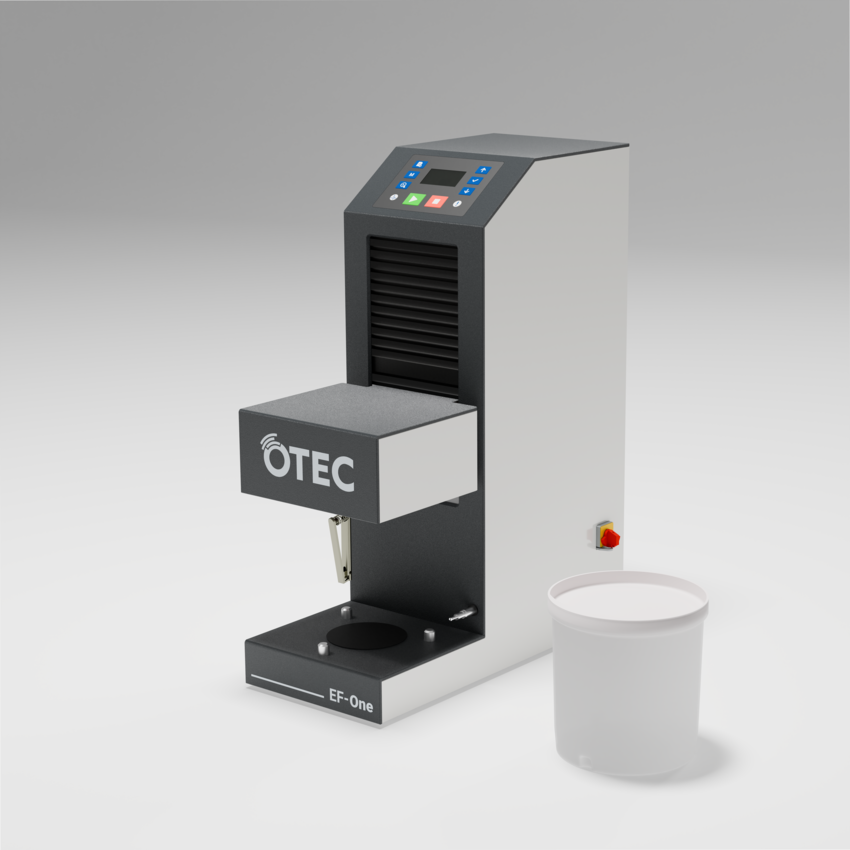

EF-One

Automated Surface Finishing for the Dental Industry.

INNOVATION MEETS EFFICIENCY

The dental industry can look forward to a groundbreaking development: The new EF-One sets new standards in terms of quality, process optimization, and cost-effectiveness. A system that is easy to operate, yet advanced and budget-friendly. The result is a compact and highly efficient standalone unit, capable of processing both CoCr and titanium.

DESIGNED FOR SMALL DENTAL LABORATORIES

The EF-One is the ideal solution for dental and orthodontic labs that manufacture small components in low volumes, typically requiring significant manual effort from technicians. With its compact design and outstanding price-performance ratio, it provides small labs with an easy entry into automated surface finishing.

„Our goal in developing this product was to create a system that meets the highest quality standards while remaining competitively priced—comparable to established alternatives such as traditional electro-polishing baths," explains Luis Schumacher.

FLEXIBLE APPLICATIONS FOR DIVERSE REQUIREMENTS

The machine offers maximum versatility thanks to a wide range of workpiece holders optimized for different indications, including:

- Crowns and bridges

- Superstructures

- RPDs and cast partial dentures

- Orthodontic components such as expanders (GNEs) and molar bandsr

Each process can accommodate one holder at a time. In the case of cast partial dentures, a single unit is processed per cycle, whereas up to four orthodontic parts can be smoothed or polished simultaneously. Thanks to its optimized container system, the EF-One allows quick media changes without additional effort..

INTUITIVE OPERATION AND INNOVATIVE TECHNOLOGIES

Developed specifically for the dental industry, the EF-One includes several features that simplify operation:

- Plug-and-Play-System: Quick and hassle-free setup saves time and reduces training requirements.

- Eight pre-installed programs: No specialized knowledge is needed, making the EF-One ideal for beginners and small labs.

- Intelligent Media Container Recognition: The container stores information about the process media and operating hours, enabling the activation of the corresponding functions. Automated assignment ensures that only compatible OTEC process media are approved.

- Guide-through-Menu: A user-friendly navigation system guides the operator through functions, minimizing errors and increasing productivity.

AUTOMATION AND PERFORMANCE POTENTIAL

The EF-One impresses with its ease of use and automation. Time-consuming manual work such as rubberizing, polishing, and grinding is reduced by up to 70%. With this compact all-in-one system, users can even test and validate titanium processing without the need for additional investments.

THE SMART CHOICE FOR MODERN DENTAL LABS

The EF-One sets new benchmarks in surface finishing. With an unbeatable price-performance ratio, it is tailored for small and medium-sized labs that require precise and efficient results—without compromising on quality or flexibility.

Thanks to innovative features such as the intelligent media container and an intuitive menu interface, the EF-One is exceptionally user-friendly. At the same time, it enables seamless processing of CoCr and titanium—a rare capability in this price segment.

In a market dominated by expensive and complex solutions, the EF-One provides a real alternative for cost-sensitive and specialized customers.

Your contact person:

Luis Schumacher

Product Manager

OTEC Präzisionsfinish GmbH

Heinrich-Hertz-Strasse 24

75334 Straubenhardt

Sales: +49 (0) 7082 / 49 11 711

E-mail: info@otec.de