TOOL INDUSTRY

Mass Finishing Systems from OTEC offer comprehensive and significant improvements in the quality and performance of cutting, stamping, forming, bending, and machining tools. This means longer tool life, consistent quality, predictability, and machine processing to replace costly manual labor. The machining process ensures the highest efficiency and quality control, optimizes your processes, and reduces manual effort.

Depending on the requirements, processes such as edge rounding, deburring, smoothing, or polishing are applied. A defined edge rounding significantly increases the tool life of cutting tools. Smoothing processes lead to fewer breakouts and better chip removal, while polishing processes achieve surface roughness values down to 0.02 µm and minimize corrosion on tool holders.

Download

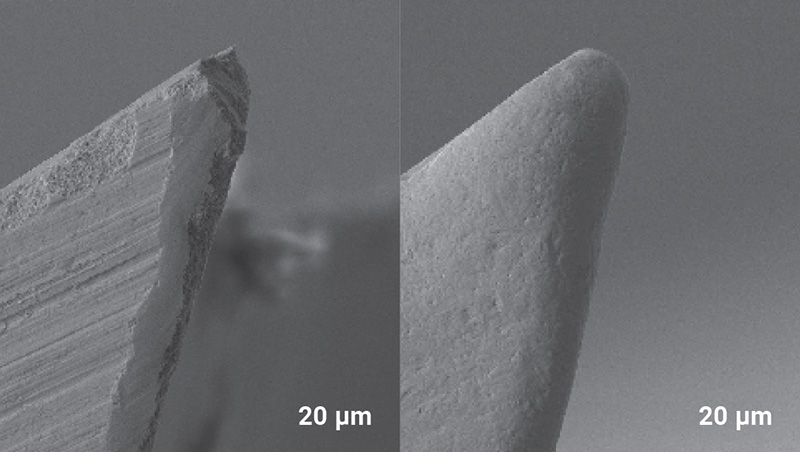

EDGE

ROUNDING

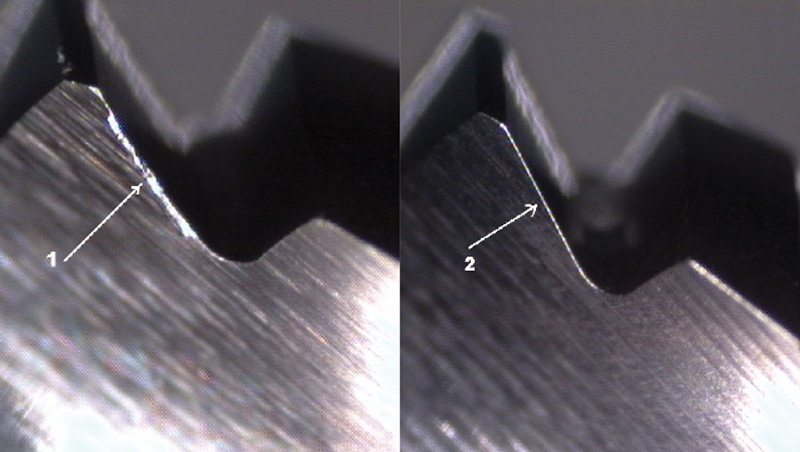

Targeted edge rounding of 5 - 100 µm stabilizes the cutting edge and reduces chipping. This results in improved surface quality and increased cutting performance. Tool life is extended by up to 3.5 times, while heat generation and wear are minimized.

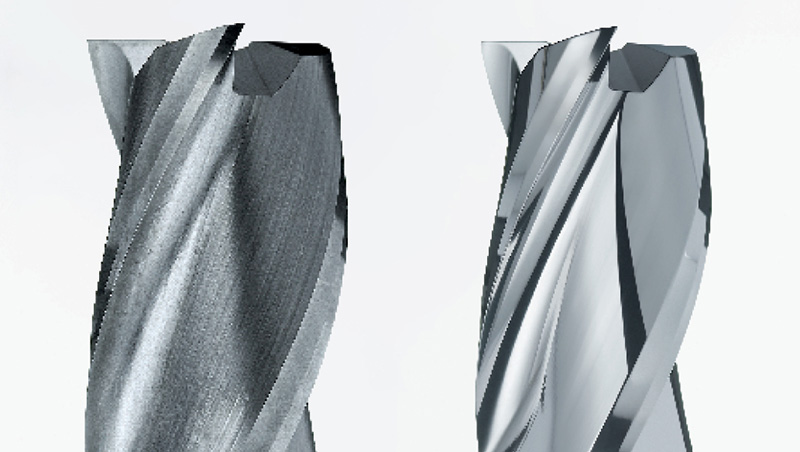

Polishing

MACHINING

Polishing the chip groove stabilizes the cutting edge and reduces surface roughness. This improves chip removal and prevents chip clamping. Cutting forces are lowered, reducing tool wear and optimizing the surface of the workpiece.

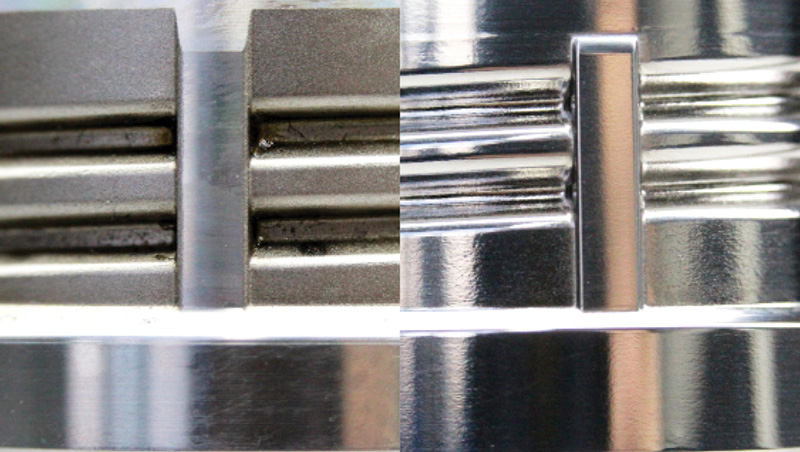

Thread Former

PROCESSING

Targeted rounding of form edges and homogenization of the surface reduce grinding times and lower forming forces by up to 60%. The process ensures uniform edge rounding, even for various geometries, and allows for precise material removal at the form edge.

Polishing

STAMPING AND DEEP DRAWING TOOLS

Polishing stamping and deep drawing tools reduces surface roughness and improves corrosion resistance. This results in longer tool life and a better appearance, while removing attachments and deposits. Reduced friction prevents material buildup and tool wear.

Polishing

INJECTION MOLDING TOOLS

Polishing injection molding tools enhances mold release and prevents material residue adhesion. This reduces the need for manual polishing and ensures consistent quality through reproducible processes.

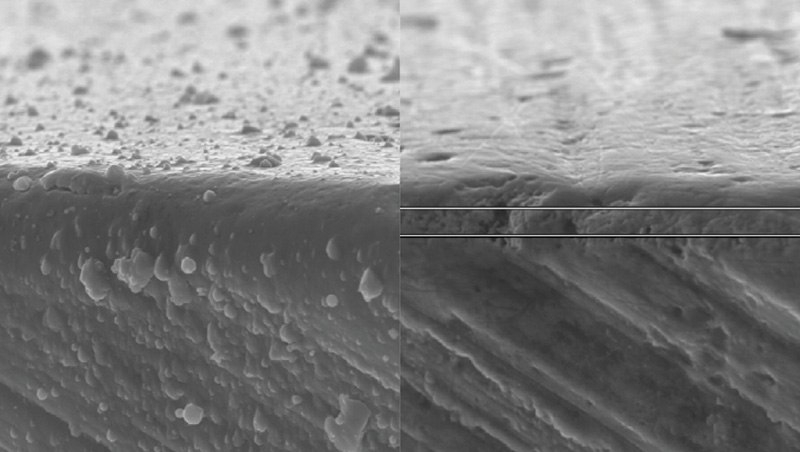

Smoothing

COATINGS

Smoothing coatings reduces friction and improves chip flow. This enhances tool performance, reduces wear, and improves chip removal. Tool life can be extended by up to 3.5 times.

Deburring

Deburring steel parts and HSS tools ensures defined edge rounding and improves tool performance. It reduces safety risks and ensures a secure fit for indexable inserts. Additionally, it provides a higher-quality tactile feel and better coating adhesion.