Smoothing | Polishing – stream finishing | Disc Finishing

Ultra-smooth surfaces on assemblies such as compressors and gearboxes are indispensable for efficient engine operation. Our customised stream finishing (SF) and disc finishing (CF) processes smooth and polish to Ra 0.01.

With process speeds up to 24 times faster than hard-to-control, chemically accelerated mass finishing, OTEC machines rise to many a challenge not only more quickly but also at lower cost and with greater process reliability. What’s more, they do away with expensive, polluting, dangerous acids and materials.

In industrial manufacturing processes for compressor blades, vanes and blisks, our customers obtain roughnesses of ~Ra 0.15 with systems tailored to their requirements.

Smooth tooth flanks and rounded tip edges boost gearbox efficiency by minimising friction and Rpk values. Another specific of the stream finishing process is that it produces lubrication valleys, significantly reducing the risk of oil film breakage – and therefore wear – to guarantee safe operation. Our stream finishing process obtains roughnesses as low as Ra 0.07 µm on high-grade hardened gears.

For piece goods

Serie SF Manual Series

Stream finishing machines with optional pulse finishing, for manual workpiece loading, suitable for e.g. small batches or non-takt production lines.more

For piece goods

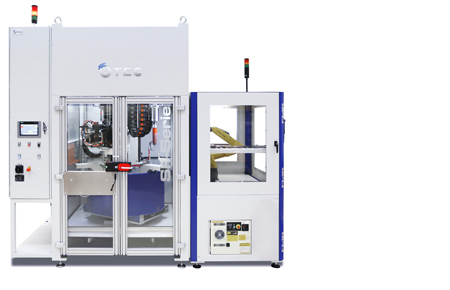

SF Automation Series

Stream finishing machines with optional pulse finishing, for automatic workpiece loading, suitable e.g. for takt production lines. Set up for automatic loading or fitted with it as an integrated option. more

For bulk goods

CF Series

Years of experience have gone into our CF Series disc finishing machines, which are designed for rapid, flawless surface processing on bulk parts.

more