Efficient precision finishing with EF-Smart T and Maxi-Dental polishers

Smooth and shiny non-precious metal restorations and splints in everyday laboratory work

Process optimization, cost-effectiveness, reliably high quality and more efficient handling in the production of model castings and custom-made occlusal splints - with EF-Smart T and Maxi-Dental, the Straubenhardt-based company OTEC provides a unique device concept for the efficient polishing and smoothing of cast and 3D-printed restorations in everyday laboratory work.

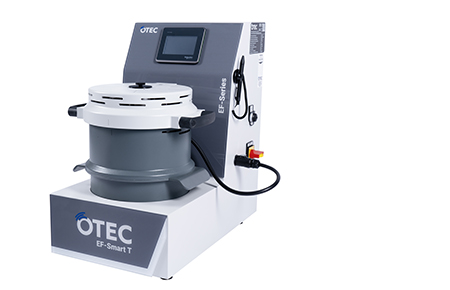

EF-Smart T for smooth and shiny non-precious metal restorations

The previous manual non-precious metal workflow is becoming increasingly economical thanks to CAD/CAM digitization in the dental laboratory. The EF-Smart T sets a milestone in this respect: based on electrochemical processes, it enables an effective polishing process. Time-consuming manual work such as gumming and pre-polishing is thus completely eliminated.

EF-Smart T is perfect for model casting, combination work, bars, full-cast crowns, bridges and partially veneered frameworks as well as delicate orthodontic parts. Dental technicians can flexibly load the device with up to 3 model casts or 12 crowns. The process time of just 20 minutes ensures greater productivity in the laboratory.

Highlights of the EF-Smart T

- No need for manual work such as rubberizing, polishing and polishing bath

- Reduction in process time by 70%

- Homogeneous polishing even on geometries that are difficult to access

- No loss of shape while maintaining tolerances

- Clean working conditions thanks to dust and acid-free processe

Maxi-Dental for perfect surfaces on splints

Polishing, smoothing and thus the surface finish with the Maxi-Dental for bite splints and full dentures is just as efficient. The PMMA splints are polished and smoothed using the mass finishing technique.

The time-consuming manual polishing process is completely replaced. Up to five workpieces are smoothed and polished in just 2 hours.

Highlights of the Maxi-Dental

- Machine processing without manual reworking

- Targeted polishing for hard-to-reach surfaces

- Fast return on investment thanks to low process costs and automation of manual processes

- Sustainable production by relieving employees and substituting processes that are hazardous to health

- Ergonomic design and easy handling of the machines

Contact address:

OTEC Präzisionsfinish GmbH

Heinrich-Hertz-Strasse 24

75334 Straubenhardt

Sales: +49 (0) 7082 / 49 11 711

E-mail: info@otec.de

Press contact:

Nordquadrat PR + Marketing

Claudia Gabbert

Gilcherweg 64 a

D-22393 Hamburg

Phone: 040/600 13 788

Mail: c.gabbert@nordquadrat.de